Tsis yog-ferrous hlau tau ci nyob rau hauv ntau qhov chaw ntawm lub neej niaj hnub no vim lawv lub cev thiab tshuaj lom neeg tshwj xeeb. Hauv kev lag luam ntawm lub taub hau, cov hlau tsis yog hlau kuj ua lub luag haujlwm tseem ceeb. -Raws li cov alloys, nrog zoo heev tshuaj stability thiab mechanical zog, muaj peev xwm ua hauj lwm stably nyob rau hauv huab ib puag ncig, ua tau raws li cov kev cai nruj ntawm cov no.sab saum toj kev lag luam thiab dhau los ua cov khoom tseem ceeb los xyuas kom meej cov cuab yeej muaj kev nyab xeeb thiab ua haujlwm tau zoo.

Sida Head yog lub hauv paus chaw tsim khoom uas tsom rau kev muab cov kev pabcuam zoo rau koj rau cov hlau tsis-ferrous lub taub hau kom tau raws li koj cov kev xav tau ntau yam.

Muaj zog technical zog, ua tau raws li cov neeg siv khoom xav tau

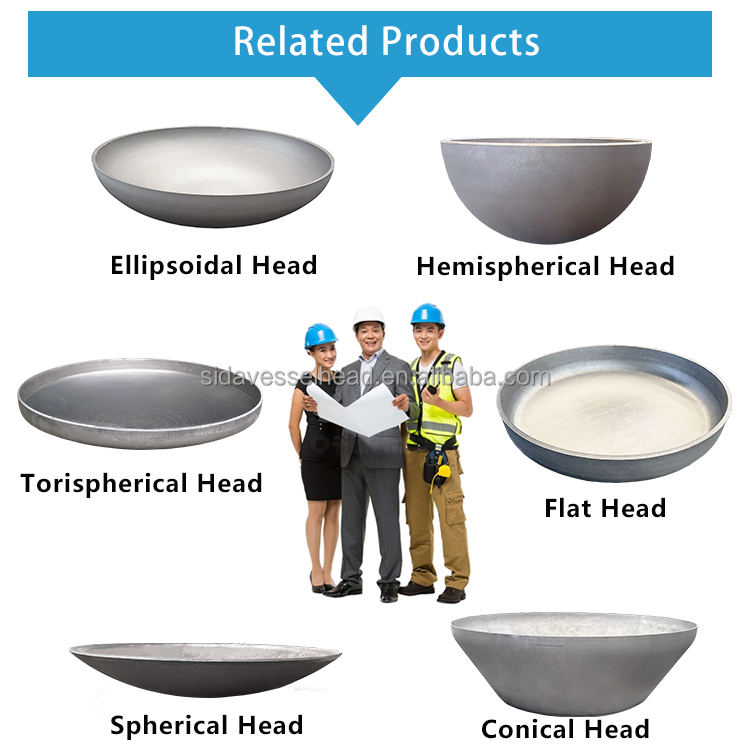

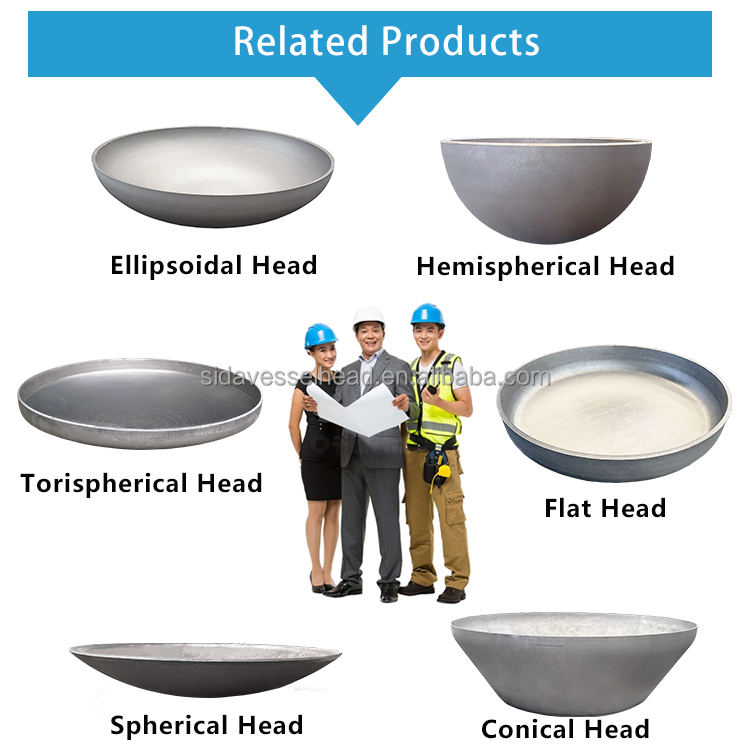

Sida Lub Taub Hau muaj kev paub dhau los hauv kev ua lub taub hau thiab ntau lawm. Hoobkas yog nruab nrogib a 3-ton stamping tshuab, 6.5-metertshuab, CNC polishing tshuab, thiab plasma tsis siv neeg vuam system, ua tiavhauv tag nrho cov txheej txheem automation los ntawm kev txiav, sib sau rau saum npoo kho,thiab-Raws li cov alloys, Sida tau txhim kho cov khoom ua tau zoo los ntawm kev kho cua sov, txias spinning txheej txheem optimization, thiab kev kho deg passivation, ua tau raws li cov qauv nruj ntawm kev lag luam nuclear, aerospace thiab lwm yam kev lag luam.

Muab pkhoom customization, cracking kev lag luam mob cov ntsiab lus

' qhov project.

Sida Lub taub hau ib txwm tau cog lus los muab cov neeg siv khoom nrog cov khoom zoo ntawm lub taub hau, teb rau txhua qhov kev cia siab nrog qhov zoo. s manufacturing kev lag luam thiab sib koom ua ke sau ib tshooj tshiab nyob rau hauv industrial manufacturing.

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek